Titanium mesh, can be used as corrosion resistance anode, filtering for corrosive substance. Sacrificial anode is the unique usage for titanium mesh.

Titanium expanded mesh is expanded from titanium sheets, the openings are normally diamond. Most common material is grade 2 C.P. Titanium.

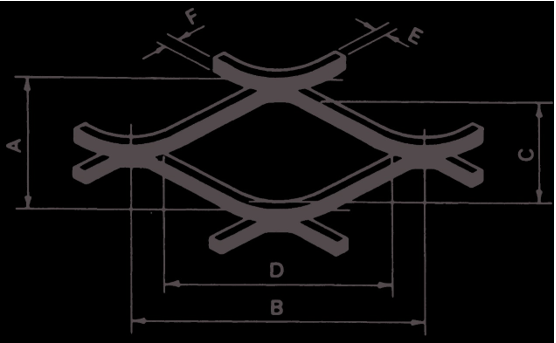

TERMINOLOGY

A: S.W.D.: Short Way Diamond

B: L.W.D.: Long Way Diamond

C: Bond: Area where strands intersect

D: Strand Width: Surface area of metal strips forming diamond

E: Strand Thickness: Gauge of material being expanded

F: Flattening: Flattened short dimension diamond parallel to rolls Cross

Flattening*: Flattened long way diamond parallel to rolls

Deburring: Mesh passed through wire brushes to remove burrs

Levelling: Mesh roller levelled to reduce curving

*Cross flattening results in distortion of the diamond in expanded mesh.

EXPANDED MESH – TYPE A: STANDARD EXPANDED MESH

It is the original and most popular type of expanded mesh with the familiar diamond shaped opening. The strands are turned at a sharp angle to the plane of the sheet giving a dimensional appearance to the finished material. The final mesh thickness will be larger than raw sheet thickness.

EXPANDED MESH – TYPE B: FLATTENED EXPANDED MESH

It is produced by passing standard mesh through heavy rolls that flat- ten the strands and bridges to pro- vide an overall level surface. This process, which reduces the original thickness by approximately one gauge, delivers a product particularly suited to applications where a slidable surface is required. The final mesh thickness will be the same as raw titanium sheet thickness.

https://www.edge-techind.com/category/Titanium-Mesh-69-1.html

https://www.edge-techind.com/Products/Non-ferrous-Metals/Titanium-Ti/Titanium-Mesh/Titanium-Mesh-157-1.html