Tungsten is an incredibly useful element that has been used extensively over the years in various manufacturing processes. It's extremely hard, heat-resistant, and corrosion-resistant, so it can be fashioned into a variety of shapes for many industrial uses. In this article, we'll discuss some of the innovative ways tungsten is being used in tube manufacturing today and its potential applications as well. From its history to advances in production methods, you will gain a better understanding of how beneficial tungsten tubes are becoming for businesses and industries around the world. So whether you are in search of a reliable partner to fabricate your next project or just want to explore more about how manufacturers are incorporating tungsten metal into new technology - read on and learn all there is to know about this incredible material!

Cutting-edge technologies in Tungsten Tube Production

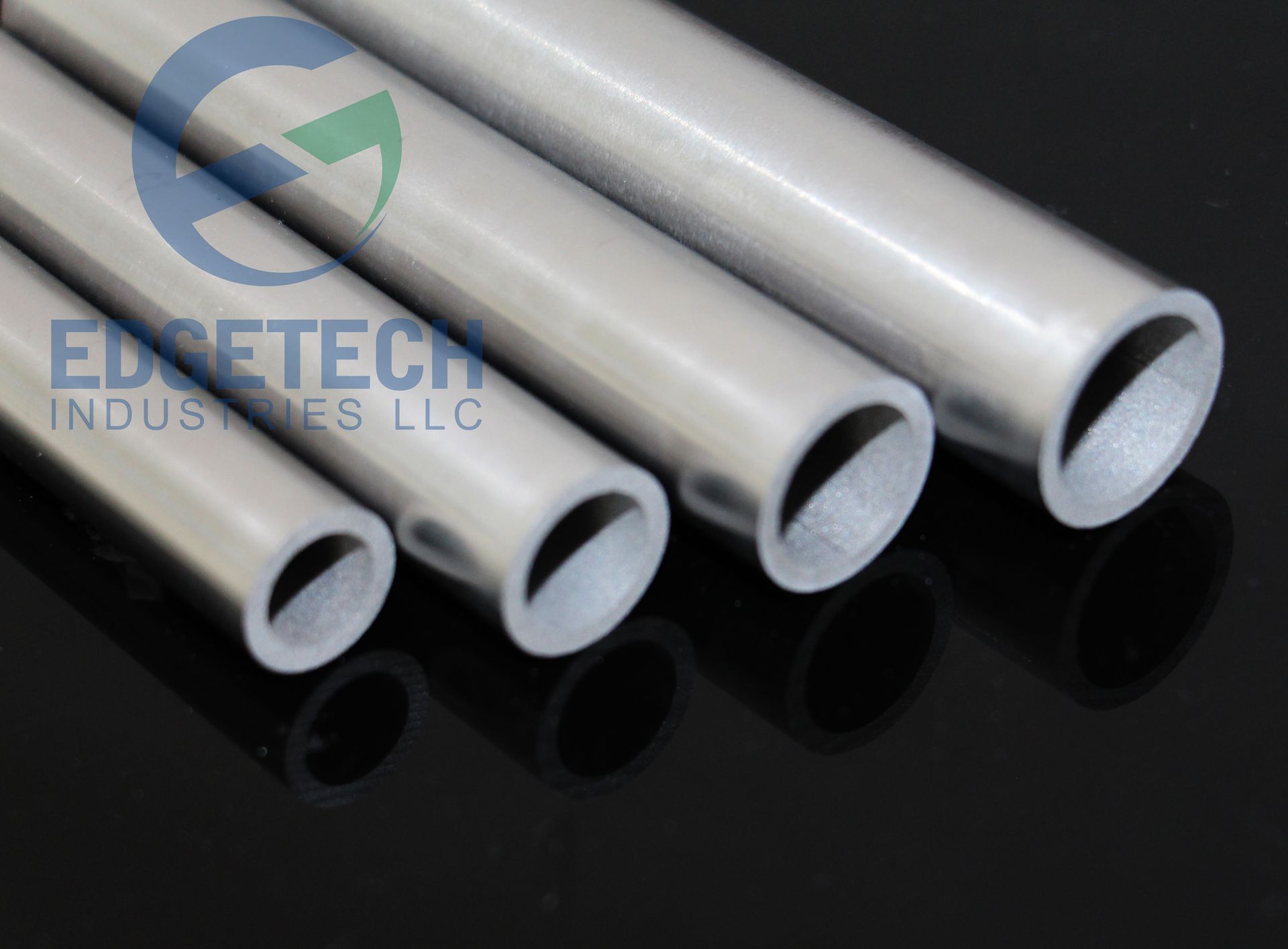

The world of manufacturing is constantly evolving, and as technology advances, so do the capabilities of production processes. One such process that has seen significant advancements in recent years is tungsten tube production. Cutting-edge technologies have enabled manufacturers to produce tungsten tubes more efficiently and effectively than ever before. These tubes are known for their strength and durability, making them a popular choice in a variety of industries. With the use of these advanced technologies, manufacturers can produce tungsten tubes to incredibly high standards, ensuring that they meet the needs of even the most demanding applications. As technology continues to improve, we can only expect to see further advancements in the production of tungsten tubes and other industrial materials.

The Importance of Tungsten Tubes in High-Temperature Environments

The use of tungsten tubes in high-temperature environments has become increasingly important in various industries. Tungsten is known for its unique properties, such as a high melting point and excellent strength. These tubes are commonly used in applications that involve extreme heat, such as furnace components, thermocouple protection, and electrical contacts. With their exceptional heat resistance and durability, tungsten tubes are highly valued in industries such as aerospace, automotive, and electronics. By incorporating tungsten tubes into high-temperature applications, manufacturers can improve the reliability and longevity of their products, ensuring they can withstand the most extreme conditions. The continued advancement and optimization of tungsten-based materials has opened up new possibilities for the design and development of cutting-edge technologies.

Balancing Durability and Precision in Tungsten Tube Design

Designing a tungsten tube that strikes the perfect balance between durability and precision is no easy feat. However, it's a challenge that engineers and designers in the industry are eager to take on. Tungsten tubes are widely used in a variety of applications, from aerospace to medical equipment. On the one hand, they need to be sturdy enough to handle extreme temperatures and harsh environments; on the other, they require a high degree of accuracy to function properly. Achieving both of these goals in a single design requires careful consideration of factors such as material composition, internal structure, and manufacturing processes. But with the right expertise and innovation, tungsten tube design is becoming more efficient and effective, leading to better products and solutions for users across industries.

Overall, the use of tungsten tubes in high-temperature environments is essential and must be addressed proactively. Through careful consideration of design parameters, components, production methods, and cutting-edge technologies, we can achieve a balance between durability and precision in tungsten tube development. The importance of having skilled experts who understand the nuances of designing for these extreme environments should not be underestimated. An experienced engineering partner can help define and produce the solutions needed to produce reliable components for superior exploitation safety and cost savings over the life cycle of your project. So make sure you reach out to an experienced engineering team before it's too late, as leveraging their expertise early on may help you save time and money.

https://www.edgetechmat.com/product/tungsten-tube/

https://www.edge-techind.com/category/Tungsten-W-22-1.html